Dongguan Jixuan Electronic Materials Co., Ltd.

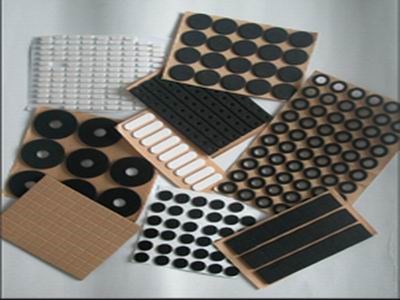

Product introduction: EVA foam molding, the performance required by customers choose the type of foam (EVA, CR, SBR, XPE, PORON, S&K, RB, as the base material, single-sided or double-sided back 3M double-sided tape, composite single-silicon Or double-silicon release material is die-cut and stamped. It is flexible, light in weight, good in density and rich in elasticity. It can be used as a buffer material to protect the product, better absorb and disperse the external impact force, and can also be attached to the surface of the product for shock resistance. Anti-friction function. At the same time, it has a series of superior use characteristics such as heat preservation, moisture resistance, corrosion resistance, etc. It is currently widely used in the packaging of IT, electronic appliances, hardware and electrical machinery, glass products, precision instruments and other products.

Instructions:

1. Before pasting, remove the dust and oil on the surface of the adhering object, and keep it dry (do not paste it when the wall is wet even on rainy days). If it is used to paste the mirror surface, it is recommended to clean the adhesive surface with alcohol first.

2. The working temperature should not be lower than 10 ℃ when pasting, otherwise the adhesive tape and the pasting surface can be properly heated with a hair dryer.

3. The pressure-sensitive tape has the best effect after being pasted for 24 hours (the tape should be pressed as tightly as possible when pasting), so when pasting vertical load-bearing objects such as mirrors, etc., when both sides have been adhered, place it flat first 24 hours. If there is no such condition, within 24 hours of vertical adhesion, support the load-bearing object.

characteristic:

1. It has excellent sealing performance to avoid gas release and atomization.

2. Excellent resistance to compression deformation, that is, the elasticity is durable, which can ensure long-term shock protection of accessories.

3. It is flame-retardant, does not contain harmful and toxic substances, will not remain, will not pollute the equipment, and is not corrosive to metals.

4. Can be used in a variety of temperature ranges. Available from minus degrees Celsius to degrees.

5. The surface has excellent wettability, easy to bond, easy to manufacture and easy to punch.

6. Long-lasting stickiness, great peeling off, strong initial stickiness, and good weather resistance! Waterproof, solvent-resistant, high-temperature resistant, and has good conformability on curved surfaces.